10-K: Annual report pursuant to Section 13 and 15(d)

Published on March 19, 2018

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K

(Mark One)

☒ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

For the fiscal year ended December 31, 2017.

OR

☐TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

For the transition period from to

Commission file number 001-38066

Select Energy Services, Inc.

(Exact name of registrant as specified in its charter)

|

Delaware |

|

81‑4561945 |

|

(State or Other Jurisdiction of Incorporation or Organization) |

|

(I.R.S. Employer Identification No.) |

|

|

|

|

|

515 Post Oak Boulevard, Suite 200 Houston, Texas |

|

77027 |

|

(Address of Principal Executive Offices) |

|

(Zip Code) |

Registrant’s telephone number, including area code (713) 235-9500

Securities registered pursuant to Section 12(b) of the Act:

|

Title of each class |

|

Name of each exchange on which registered |

|

|

|

|

|

Class A Common Stock $0.01 par value |

|

New York Stock Exchange |

Securities registered pursuant to Section 12(g) of the Act:

NONE

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act.

|

Yes ☐ |

|

No ☑ |

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act.

|

Yes ☐ |

|

No ☑ |

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days.

|

Yes ☑ |

|

No ☐ |

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Website, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files).

|

Yes ☑ |

|

No ☐ |

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K (§299.405 of this chapter) is not contained herein, and will not be contained, to the best of the registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. ☐

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, a smaller reporting company or an emerging growth company. See the definitions of “large accelerated filer,” “accelerated filer,” “smaller reporting company” and “emerging growth company” in Rule 12b-2 of the Exchange Act.

|

Large accelerated filer |

☐ |

Accelerated filer |

☐ |

|

Non-accelerated filer (Do not check if a smaller reporting company) |

☑ |

Smaller reporting company |

☐ |

|

Emerging growth company |

☑ |

|

|

If an emerging growth company, indicate by check mark if the registrant has elected not to use the extended transition period for complying with any new or revised financial accounting standards provided pursuant to Section 13(a) of the Exchange Act. ☐

Indicate by check mark whether the registrant is a shell company (as defined by Rule 12b-2 of the Exchange Act).

|

Yes ☐ |

|

No ☑ |

The aggregate market value of the voting and non-voting common stock held by non-affiliates of the registrant computed as of June 30, 2017 (the last business day of the registrant’s most recent completed second fiscal quarter) based on the closing price of the Class A common stock on the New York Stock Exchange was $322.1 million. There were 59,290,665, 6,731,839 and 40,331,989 shares of the registrant’s Class A, Class A-2 and Class B common stock, respectively, outstanding as of March 15, 2018.

Documents Incorporated by Reference:

Portions of the registrant’s definitive proxy statement for the 2018 annual meeting of stockholders, to be filed no later than 120 days after the end of the fiscal year, are incorporated by reference into Part III of this Annual Report on Form 10-K.

1

CAUTIONARY NOTE REGARDING FORWARD-LOOKING STATEMENTS

The information in this Annual Report on Form 10-K includes “forward‑looking statements” within the meaning of Section 27A of the Securities Act of 1933, as amended (the “Securities Act”), and Section 21E of the Securities Exchange Act of 1934, as amended (the “Exchange Act”). All statements, other than statements of historical fact, included in this Annual Report regarding our strategy, future operations, financial position, risks, estimated revenues and losses, projected costs, prospects, plans and objectives of management are forward‑looking statements. When used in this Annual Report, the words “could,” “believe,” “anticipate,” “intend,” “estimate,” “expect,” “project,” “preliminary,” “forecast” and similar expressions or variations are intended to identify forward‑looking statements, although not all forward‑looking statements contain such identifying words. When considering forward‑looking statements, you should keep in mind the cautionary statements included in this Annual Report. These forward‑looking statements are based on management’s current belief, based on currently available information, as to the outcome and timing of future events. Important factors that could cause actual results to differ materially from those in the forward‑looking statements include, but are not limited to, those summarized below:

•the ultimate outcome and results of integrating our operations with the operations of Rockwater (as defined herein);

•the effects of our business combination with Rockwater, including the combined company’s future financial condition, results of operations, strategy and plans;

•potential adverse reactions or changes to business relationships resulting from the completion of the Rockwater Merger (as defined herein);

•expected benefits from the Rockwater Merger and the ability of the combined company to realize those benefits;

•the results of any merger‑related litigation, settlements and investigations;

•the level of capital spending by U.S. and Canadian oil and gas companies;

•trends and volatility in oil and gas prices;

•demand for our services;

•regional impacts to our business, including our key infrastructure assets within the Bakken;

•our level of indebtedness and our ability to comply with covenants contained in our Credit Agreement (as defined herein) or future debt instruments;

•our access to capital to fund expansions, acquisitions and our working capital needs and our ability to obtain debt or equity financing on satisfactory terms;

•our safety performance;

•the impact of current and future laws, rulings and governmental regulations, including those related to hydraulic fracturing, accessing water, disposing of wastewater and various environmental matters;

•our ability to retain key management and employees;

•the impacts of competition on our operations;

2

•our ability to hire and retain skilled labor;

•delays or restrictions in obtaining permits by us or our customers;

•constraints in supply or availability of equipment used in our business;

•the impacts of advancements in drilling and well service technologies;

•changes in global political or economic conditions, generally, and in the markets we serve;

•accidents, weather, seasonality or other events affecting our business; and

•the other risks identified in this Annual Report including, without limitation, those under the headings “Item 1A. Risk Factors,” “Item 1. Business,” “Item 7. Management’s Discussion and Analysis of Financial Condition and Results of Operations” (“MD&A”) and “Item 13. Certain Relationships and Related Transactions, and Director Independence.”

These factors are not necessarily all of the important factors that could cause actual results to differ materially from those expressed in any of our forward‑looking statements. Other unknown or unpredictable factors also could have material adverse effects on our future results. Our future results will depend upon various other risks and uncertainties, including those described elsewhere in this Annual Report. Readers are cautioned not to place undue reliance on forward‑looking statements, which speak only as of the date hereof. We undertake no obligation to update or revise any forward‑looking statements after the date they are made, whether as a result of new information, future events or otherwise. All forward‑looking statements attributable to us are qualified in their entirety by this cautionary statement.

References Within This Annual Report

As used in Part I of this Annual Report on Form 10-K, unless the context otherwise requires, references to the ”Company,” ”we,” ”our,” ”us” or similar expressions refer (1) for time periods prior to our December 2016 private placement of 16,100,000 shares of our Class A-1 common stock at $20.00 per share (the “Select 144A Offering”) and the related corporate reorganization transactions to Select Energy Services, LLC (“Select LLC”) and SES Holdings, LLC (“SES Holdings”) and their consolidated subsidiaries, (2) for time periods after the Select 144A Offering and the related corporate reorganization transactions and prior to the Rockwater Merger and the related corporate reorganization transactions, to Select Energy Services, Inc. (“Select Inc.”) and its consolidated subsidiaries and (3) after the Rockwater Merger and the related corporate reorganization transactions, to Select Inc. and its consolidated subsidiaries, including those subsidiaries acquired in the Rockwater Merger. Additionally, prior to the consummation of the Rockwater Merger and the related corporate reorganization transactions, “Rockwater” refers to Rockwater Energy Solutions, Inc. and its consolidated subsidiaries and “Rockwater LLC” refers to Rockwater Energy Solutions, LLC and its consolidated subsidiaries. Following the consummation of Rockwater Merger and the related corporate reorganization transactions “Rockwater” refers to Select Energy Solutions (RW), Inc. and its consolidated subsidiaries and “Rockwater LLC” refers to Rockwater Energy Solutions, LLC and its consolidated subsidiaries.

3

We are a leading provider of total water management and chemical solutions to the unconventional oil and gas industry in the United States and Western Canada. We were formed as a Delaware corporation in November 2016. Within the major shale plays in the United States, we believe we are a market leader in sourcing, transfer (both by permanent pipeline and temporary hose) and temporary containment of water prior to its use in drilling and completion activities associated with hydraulic fracture stimulation or “fracking,” which we collectively refer to as “pre‑frac water services”. In addition, we provide testing and flowback services immediately following the well completion. In most of our areas of operations, we also provide additional complementary water‑related services that support oil and gas well completion and production activities, including monitoring, treatment, hauling, water recycling and disposal. We also manufacture a full suite of specialty chemicals used in well completions, and we provide chemicals needed by our customers to help increase oil and gas production and lower costs over the extended life of a typical well. We have historically generated a substantial majority of our revenues through providing total water solutions to our customers, and we believe we are the only company that provides total water solutions together with complementary chemical products and related expertise, which we believe gives us a unique competitive advantage in our industry.

Water is essential to the development and completion of unconventional oil and gas wells, where producers rely on fracking to stimulate the production of oil and gas from dense subsurface rock formations. The volume of water required to economically produce tight oil and gas reserves in the United States and Canada has grown more than tenfold over the past five years. Water and related services comprise a large and growing portion of our customers’ drilling and completion costs. In support of new well development, we source, transfer, provide containment of and treat the water used by our customers in the well completion process. The fracking process involves the injection of large volumes of water and proppant (typically sand) together with chemicals under high pressure, through a cased and cemented wellbore into targeted subsurface formations thousands of feet below ground to fracture the surrounding rock. Our completion chemicals are blended with water to improve the transport and placement of proppant in targeted zones within the producing formation. The induced fractures near the wellbore allow hydrocarbons to flow into the wellbore for extraction. Our team of chemists and research and development personnel work with our customers to optimize the frac fluid system. Up to fifty percent of the water pumped into the well during the fracking process returns as “flowback” during the first several weeks following the well completion process, and a large percentage of the remainder, plus pre‑existing water in the formation, is recovered as produced water over the life of the well. This flowback and produced water must be captured, contained and either disposed of in an environmentally safe manner, or treated and recycled for reuse in subsequent frack jobs. We provide services that support the operator’s management of flowback and produced water. After the fracking process is completed, we provide a variety of services related to the initial phase of the flowback and production operations that complement the longer‑term oil and gas production activities, including designing and executing chemical treatment programs to improve well productivity, extend the useful life of wells and reduce production costs.

4

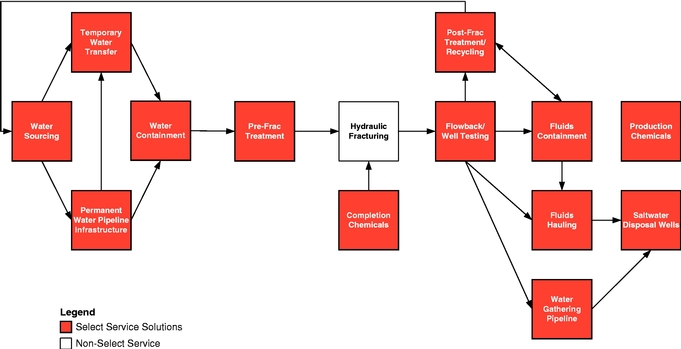

The diagram below illustrates the primary water solutions and oilfield chemicals services we provide during the completion and production cycle of a horizontal well:

As the development of unconventional reservoirs has evolved over the past decade, the total volumes of water required in the fracking process have grown dramatically. Management estimates that the completion of a horizontal well in 2009 required an average of approximately 75,000 barrels of water or approximately 575 tank truck loads. Today, current horizontal well completions can require in excess of 500,000 barrels per well or roughly 3,850 tank truck loads. Multi‑well pad completions can require in excess of 5 million barrels of water per pad, or the equivalent of 38,500 tank truck loads. Significant mechanical, logistical, environmental and safety issues related to the transfer and subsequent containment of such large volumes via tank truck have resulted in tank trucks no longer representing a viable solution for the transport of frack water. Accordingly, E&P companies have shifted their pre-frac operational focus away from traditional tank truck operators and small, local water service providers, to larger, regional and national players, like us, who have the expertise, technology and scale to provide high quality, reliable, comprehensive and environmentally sound water services.

The total volumes of flowback and produced water are even greater―by some estimates, the U.S. oil and gas industry today produces over 20 billion barrels of water per year and this volume is likely to grow. We believe the industry will increasingly turn to companies like us to help cost effectively manage produced water in an environmentally responsible way.

We believe our broad geographic footprint, comprehensive suite of water services, inventory of water sources and permanent and temporary pipeline infrastructure position us to be a leading provider of water solutions in all of the shale plays that we serve. We have well‑established field operations in what we believe to be core areas of many of the most active shale plays in the United States and Canada, including the Permian Basin, SCOOP/STACK, Bakken, Eagle Ford, Haynesville, Marcellus, Utica, Rockies (DJ/Niobrara, Powder River and Uinta), other Mid‑Continent (“MidCon”) basins (Woodford, Barnett, Fayetteville, Granite Wash and Mississippian) and Western Canada. Our broad footprint enables us to service the majority of current domestic unconventional drilling and completions activity. We estimate that over 80% of all currently active U.S. onshore horizontal rigs are operating in our primary service areas and anticipate that the vast majority of rigs that will be deployed in the near‑ to medium‑term will be situated in these areas. In particular, we have established a strong position in the Permian Basin, which is presently our largest operating region,

5

and where producers are continuing to invest significant capital as commodity prices continue to recover from recent lows.

We seek to be a comprehensive provider of total water management and chemical solutions for our customers in most of our areas of operations. We have the capability to provide all of the pre-frac water services and many of the complementary chemicals our customers require in their drilling and completion activities, including the sourcing, transferring, containing, treatment, testing and monitoring of water. We also offer various complementary water‑related services that support oil and gas completion and production activities, including well testing, flowback, post-frac fluid hauling, pipeline gathering, treatment, recycling and disposal of water. In addition, we develop and manufacture a full suite of production chemicals used to enhance performance over the life of a well.

On the pre-frac side our Water Solutions segment’s inventory of water sources is a key competitive advantage that enables us to offer our customers reliable access to the volume of water essential for fracking operations. Water sources are often difficult to locate, acquire and permit, particularly in the quantities needed for multi‑well pad development programs. We have spent years obtaining strategic water sources and have secured permits or long‑term access rights to approximately 1.5 billion barrels of water annually from hundreds of sources, including large scale sources such as the Brazos, Missouri, Navasota, Ohio, Rio Grande, Sabine, San Antonio and Washita Rivers. In the Bakken, for example, we believe we have established a market leading position by securing three governmental permits which enable us to withdraw up to 100 million barrels of water annually from the Missouri River and Lake Sakakawea in North Dakota. Fresh water access cannot be easily replicated on Lake Sakakawea today as there are multiple environmental and regulatory conditions that must be met before an industrial water intake location can be built. New permits will also not be granted within 25 miles of an intake location associated with an existing permit. We have three of the five existing permits off Lake Sakakawea. In addition to surface water rights, groundwater resources are a key component of our extensive water portfolio. These sources have been secured or developed within our Water Solutions group and are designed with dedicated containment and transfer logistics to offer a complete water management solution. The first step in procuring a water source is identifying an area of interest based on anticipated drilling and completion activity as a result of lease activity, applications for permits and industry sources. After a specific water source is identified, we perform an assessment of the particular prospective source, including confirming availability, regulatory status, and any limitations on potential water rights. We use our AquaView® technology to quantify volumes and flow rates to verify current and potential water availability and volumes. After confirming the relevant ownership information, we begin negotiations with the applicable landowner or holder of the water rights. After finalizing the agreements and access rights, our team will obtain necessary regulatory approvals, permits and rights‑of‑way as needed based on the regulatory authorities involved and individual circumstances. Going forward, we believe that our expertise and relationships in water sourcing will provide us with a competitive advantage in identifying and securing additional sources of water. Additionally, water is increasingly becoming sourced through the reuse of produced or flowback water from existing wells that has been subjected to various treatment or fresh water blending options. We have a dedicated team of individuals focused on developing water treatment and reuse services to our customers and although water reuse has been a relatively small percentage of our revenue to‑date, we believe demands for our water reuse services will increase as water demands increase, regulatory restrictions increase, disposal options decrease, water treatment costs decline and operators reevaluate the reuse of treated flowback and produced water in their completion programs.

We also manage the transfer of water from the source, between containments and ultimately to the wellsite for well completion. We have invested significant capital in temporary pipe, including approximately 1,400 miles of lay‑flat hose, and other related assets. Our lay‑flat hose provides a flexible water transfer solution and can be customized to fit a specific project. After the completion of a project, lay‑flat hose can be quickly and cost‑effectively removed and redeployed for a new project. These investments enable us to provide our customers with temporary water transfer systems that have substantially lower risk of leaks or spills compared to many alternative temporary piping options. We believe our expansive inventory of lay‑flat hose, in combination with our customers’ preference for this temporary water transfer method, positions us to be a market leader for this class of water transfer services. To support our water sourcing and transfer services, we have also made significant investments in strategic permanent pipelines that provide reliable and cost effective water delivery. Our most significant pipeline assets are located in the Bakken and allow us to take advantage of our water permits in that region. Our Bakken pipelines consist of two active underground pipeline systems, the Charlson and the Iverson systems, in McKenzie County, North Dakota that can currently deliver up to 62 million barrels of fresh water per year. We are in the process of developing a third underground pipeline to support Williams

6

County and western Mountrail County in North Dakota that would allow us to fully utilize our annual water rights in this region. We have signed long‑term contracts supported by Areas of Mutual Interest with major Bakken producers that we believe will use a significant portion of our current pipeline capacity. We have also made investments outside of the Bakken, including our pipeline serving the SCOOP area of Oklahoma, the “Pecan Hill Pipeline,” and our pipeline serving the Haynesville, the “IP Pipeline.” Additionally, with the GRR Acquisition (as defined below) we acquired rights to a vast array of fresh, brackish and effluent water sources with access to significant volumes of water annually and water transport infrastructure, including over 1,200 miles of temporary and permanent pipeline infrastructure and related storage facilities and pumps, all located in the northern Delaware Basin portion of the Permian Basin.

In addition to water sourcing and transfer, our Water Solutions segment offers various complementary water‑related services that support oil and gas completion and production activities. Before and during the completion phase of a well, along with water sourcing and transfer, we offer water containment, monitoring and treatment solutions. Following the completion process, we provide flowback and well testing services, flowback and produced water hauling, pipeline gathering and disposal services and water treatment and recycling solutions relating to the potential reuse of flowback and produced water for new well completions. We support our customers across the life cycle of a well from completion to production and our comprehensive technical expertise related to water solutions management uniquely positions us relative to other water solutions providers to provide our customers comprehensive service solutions designed to maximize well performance, reduce costs and increase efficiencies while reducing the environmental impacts of their resource development.

Our Oilfield Chemicals segment develops, manufactures and provides a full suite of chemicals utilized in hydraulic fracturing, stimulation, cementing and well completions, including polymers that create viscosity, crosslinkers, friction reducers, surfactants, buffers, breakers and other chemical technologies, to leading pressure pumping service companies in the United States. Our production chemicals solutions, which can be applied to producing wells throughout their producing lives, are applied to underperforming wells in order to enhance well performance and reduce production costs through the use of production treating chemicals, corrosion and scale monitoring, chemical inventory management, well failure analysis and lab services. Our product lines support the full range of fluid systems utilized primarily in the completion and development of unconventional resources. The use of automated communications systems combined with direct‑to‑wellsite delivery ensures seamless product availability for our customers, while our chemical expertise enables us to deliver a customized suite of products to meet customers’ technical and economical product needs. Our expertise in frac chemistry also positions us to support our customers in developing programs to reuse produced and flowback water as an alternative to disposal. In addition to our product offering, we provide inventory management services, including procurement, warehousing and delivery services. We have two primary manufacturing facilities in Texas, five regional distribution centers and 29 heavy chemical transport trucks and provide products to our customers in all major U.S. shale basins. Rockwater will also have the first in-basin manufacturing facility of emulsion polymers (friction reducers) in our industry. The in-basin manufacturing facility is strategically located in the Permian Basin which will provide a strategic advantage of being able to reduce our overall costs of raw materials that can now be delivered directly to the basin by rail.

We also offer our customers various ancillary services through our Wellsite Services segment. Through our subsidiary, Peak Oilfield Services, LLC (“Peak”), we provide workforce accommodations and surface rental equipment supporting oil and gas drilling, completion and production operations. Through our subsidiary, Affirm Oilfield Services, LLC (“Affirm”), we provide crane and logistics services, wellsite and pipeline construction and various field services. Operating under Rockwater LLC, we also offer sand hauling and logistics services in the Rockies and Bakken regions, as well as water transfer, containment, fluids hauling and other rental services in Western Canada. We provide our Wellsite Services to a wide range of customers in many of the most active shale plays or basins in the United States and Canada.

7

We maintain a culture that prioritizes safety, the environment and our relationship with the communities in which we operate. We place a strong emphasis on the safe execution of our operations, including safety training for our employees and the development of a variety of safety programs designed to make us a market leader in safety standards. Further, our safety recognition program incentivizes employees throughout our organization to focus on conducting operations in accordance with our strict safety standards. In addition, we work closely with federal, state and local governments and community organizations to help ensure that our operations comply with legal requirements and community standards. We believe that our customers will select their service providers based in part on the quality of their safety and compliance records, and therefore, we will continue to make significant investments to be a market

leader in this area.

Recent Developments

Rockwater Merger

On November 1, 2017, we completed the transactions (the “Rockwater Merger”) contemplated by the Agreement and Plan of Merger, dated as of July 18, 2017 (the “Merger Agreement”), by and among us, SES Holdings, Raptor Merger Sub, Inc., a Delaware corporation and our wholly owned subsidiary, Raptor Merger Sub, LLC, a Delaware limited liability company and an indirect wholly owned subsidiary of SES Holdings, Rockwater and Rockwater LLC. Pursuant to the Merger Agreement, we combined with Rockwater in a stock‑for‑stock transaction in which we issued approximately 25.9 million shares of our Class A common stock, 6.7 million shares of our Class A‑2 common stock and 4.4 million shares of our Class B common stock to the former holders of Rockwater common stock and a unit‑for‑unit transaction in which SES Holdings issued approximately 37.3 million common units in SES Holdings (each, an “SES Holdings LLC Unit”) to the former holders of units in Rockwater LLC (each, a “Rockwater LLC Unit”).

Rockwater was incorporated as a Delaware corporation in March 2017. Prior to the Rockwater Merger, Rockwater was a holding company whose sole material asset consisted of a membership interest in Rockwater LLC. Rockwater’s predecessor corporation was formed as a Delaware corporation in June 2011 and converted into Rockwater LLC in March 2017.

Resource Water Acquisition

On September 15, 2017, we completed our acquisition (the “Resource Water Acquisition”) of Resource Water Transfer Services, L.P. and certain other affiliated assets (collectively, “Resource Water”). Resource Water provides water transfer services to E&P operators in West Texas and East Texas. Resource Water’s assets include 24 miles of layflat hose as well as numerous pumps and ancillary equipment required to support water transfer operations. Resource Water has longstanding customer relationships across its operating regions which are viewed as strategic to our water solutions business.

Initial Public Offering

On April 20, 2017, the registration statement on Form S‑1 (File No. 333‑216404) relating to our initial public offering (the “IPO”) was declared effective by the SEC. The IPO closed on April 26, 2017, at which time we issued and sold 8,700,000 shares of Class A common stock at a price to the public of $14.00 per share. We received cash proceeds of approximately $114.2 million from this transaction, net of underwriting discounts and commissions. On May 10, 2017, the underwriters exercised in full their option to purchase an additional 1,305,000 shares of Class A common stock at a price to the public of $14.00 per share. We received cash proceeds of approximately $17.1 million, net of underwriting discounts and commissions and estimated offering expenses, from the sale of such additional shares pursuant to the underwriters’ option. We incurred costs of approximately $2.8 million related to the IPO.

Crescent Merger

On March 31, 2017, Rockwater acquired Crescent Companies, LLC (‘‘Crescent’’), a company that provides water and fluid management solutions to E&P companies principally in the Mid Continent, Marcellus/Utica, Eagle Ford and Permian basins (the ‘‘Crescent Merger’’). A majority of Crescent’s revenue is derived from providing total water and fluid management solutions. The consideration for the Crescent Merger consisted of equity securities and the repayment of Crescent’s outstanding indebtedness, which was approximately $39.3 million, using borrowings under

8

Rockwater’s credit facility. Rockwater issued 4,105,998 shares of Rockwater Class A Common Stock and Rockwater LLC issued 5,693,258 Rockwater LLC Units and an equivalent number of shares of Rockwater Class B Common Stock to the owners of Crescent.

GRR Acquisition

On March 10, 2017, we completed our acquisition (the “GRR Acquisition”) of Gregory Rockhouse Ranch, Inc. and certain other affiliated entities and assets (collectively, the “GRR Entities”). The GRR Entities provide water and water‑related services to E&P companies in the Permian Basin and own and have rights to a vast array of fresh, brackish and effluent water sources with access to significant volumes of water annually and water transport infrastructure, including over 1,200 miles of temporary and permanent pipeline infrastructure and related storage facilities and pumps, all located in the northern Delaware Basin portion of the Permian Basin. The total consideration we paid for this acquisition was $59.6 million, with $53.0 million paid in cash, $5.5 million paid in shares of Class A common stock, subject to customary post‑closing adjustments, and $1.1 million in assumed tax liabilities to the sellers. We funded the cash portion of the consideration for the GRR Acquisition with $19.0 million of cash on hand and $34.0 million of borrowings under our Previous Credit Facility (as defined below), which we repaid with a portion of the net proceeds of the IPO. We believe this acquisition has significantly enhanced our position in the Permian Basin.

9

Description of Business Segments

Following the completion of the Rockwater Merger, we offer our services through the following three operating segments: (i) Water Solutions, (ii) Oilfield Chemicals and (iii) Wellsite Services.

Water Solutions

Our Water Solutions segment is operated primarily under our subsidiary, Select LLC, and provides water‑related services to customers that include major integrated oil companies and independent oil and natural gas producers. These services include: the sourcing of water; the transfer of the water to the wellsite through permanent pipeline infrastructure and temporary hose; the containment of fluids off‑ and on‑location; measuring and monitoring of water; the filtering and treatment of fluids, well testing and handling of flowback and produced formation water; and the transportation and recycling or disposal of drilling, completion and production fluids.

Service Lines

Our Water Solutions operating segment is divided into the following service lines:

•Water Sourcing. Our water sourcing service line helps E&P companies source water used for drilling and completion operations from our surface, ground and industrial water sources. Specifically, through a portfolio of contracts with and permits from regulatory bodies, corporations and individual landowners, we have secured rights to approximately 1.5 billion barrels of water annually from hundreds of sources, a number which varies over time, including large scale sources such as the Brazos, Missouri, Navasota, Ohio, Rio Grande, Sabine, San Antonio and Washita Rivers. In the Bakken, we have three governmental permits that enable us to withdraw up to 100 million barrels of water annually from the Missouri River and Lake Sakakawea in North Dakota. Fresh water access cannot be easily replicated on Lake Sakakawea today as there are multiple environmental and regulatory conditions that must be met before an industrial water intake location can be built. New permits will also not be granted within 25 miles of an intake location associated with an existing permit. We have three of the five existing permits off Lake Sakakawea. Additionally, the recently acquired GRR Entities have rights to a vast array of fresh, brackish and effluent water sources with access to significant volumes of water annually. In addition to primary frac water sourcing, we also source brine water and other completion fluids.

•Water Transfer. Our water transfer service line provides high‑volume, high‑rate water transfer services through permanent pipeline systems and temporary pipe systems. This service is utilized to transfer water from a source to a containment location on or off the wellsite, from the containment directly to the well to support completion operations, and, in certain circumstances, directly from the source to the well. Our assets include more than 110 miles of operational underground pipeline, approximately 1,400 miles of lay‑flat hose and approximately 1,000 high‑rate water transfer pumps. Additionally, the recently acquired GRR Entities own significant water transport infrastructure, including over 1,200 miles of temporary and permanent pipeline infrastructure and related storage facilities and pumps, all located in the northern Delaware Basin portion of the Permian Basin. The Rockwater Merger added Rockwater’s sizable fleet of small and large diameter pipe and hose and pumps to our water transfer service line and extended our water transfer service capabilities across North America. Our permanent pipeline systems are located in the Bakken, the SCOOP and the Haynesville, as described in more detail below.

•Bakken: We have invested over $30.0 million in the Charlson Pipeline and the Iverson Pipeline in the Bakken located in McKenzie County, North Dakota, and we are developing a third pipeline system that will serve Williams County and western Mountrail County. The Charlson pipeline system is located on the eastern side of McKenzie County, North Dakota, and consists of 32 miles of operational pipeline. The Iverson pipeline system is located in eastern McKenzie County, North Dakota, and consists of 58 miles of operational pipeline. Of the approximately 90 miles of underground pipeline systems, we own 38 miles and have contractual rights to access the remaining 52 miles. The development of the third permit began in late 2017 and will allow us to utilize 100 million barrels of fresh water per year across the three systems.

10

•SCOOP: Through our interest in a joint venture with Access Midstream (subsequently merged with Williams Partners), we own a nine‑mile, underground fresh water delivery pipeline in Grady County, Oklahoma in what we believe to be the core of the SCOOP, with an additional 23 miles of sour gas pipeline that can be subsequently converted to deliver fresh water. The source for this pipeline system originates from the Washita River, a reliable water source in an otherwise dry and drought‑prone region of Oklahoma. We are currently permitted by the Oklahoma Water Resources Board to withdraw 10.8 million barrels of water per year from the river, in excess of the pipeline’s current physical throughput capacity of 9.2 million barrels per year.

•Haynesville: We own an approximately 12‑mile underground fresh water delivery pipeline in De Soto Parish, Louisiana, which transports effluent from a pump station at International Paper’s Mansfield Plant Outfall No. 1 to five delivery points within the Holly Field for use in fracking operations. The IP Pipeline is located in what we believe is the core acreage of the Haynesville shale.

Our lay‑flat hose provides a flexible water transfer solution and can be customized to fit a specific project. After the completion of a project, lay‑flat hose can be quickly and cost‑effectively removed and redeployed for a new project, including projects in different geographic regions. Lay‑flat hose has a significantly lower risk of spills than most other types of temporary jointed‑pipe as a result of the strength and durability of the hose as well as the secure nature of any coupling joints used to connect multiple sections of hose. We believe the average length of lay‑flat hose used in a project is approximately 5 miles, but the length can vary from as little as a few hundred feet to as much as 75 miles for a comprehensive water management program. Our lay‑flat hose consists of 8 inch, 10 inch and 12 inch diameter segments. Depending on the requirements of a project, lay‑flat hose may run from a water source directly to a containment area or wellsite or from containment area to containment area. Our customers generally prefer lay‑flat hose to alternative temporary piping options due to the cost‑effectiveness, customizability and reduced risk of spills.

•Water Containment. We are the largest provider of high‑capacity above ground storage tanks (“ASTs”) in North America with an inventory offering water storage capacity between 4,500 and 60,000 barrels per tank with remote monitoring capability in every major U.S. basin and Western Canada. Our ASTs provide a low cost containment alternative to frac tanks and support our water treatment and reuse strategy that we bundle with our water transfer and water reuse services to provide enhanced water management solutions to our customers. A 40,000 barrel AST can be delivered by three trucks and be installed in half a day, and replaces 80 500‑barrel frac tanks. Our modular tank design allows for 20 different tank configurations to meet each customer’s individual needs, and we also offer nested tanks for complete secondary containment.

•Water Treatment and Recycling. Our water treatment and recycling service line works with oil and gas producers to treat water utilized in the drilling, completion and production processes. Additionally, we offer recycling services for the reuse of flowback, produced or otherwise impaired water for reuse in new well completions. Specifically, we offer water treatment and recycling solutions ranging from basic filtration solutions to the application of chemical disinfection and more advanced technologies, including oil removal, iron removal and the removal of other contaminants. These solutions are offered through in‑house equipment and expertise, as well as with outside strategic relationships and investments.

•Well Testing and Flowback. Our well testing and flowback service line provides highly trained personnel and state‑of‑the‑art equipment and technologies to perform a multitude of services relating to the completion and production of oil, gas, condensate and water, including frac support, frac plug drill‑out, flowback, well testing and lease operating. These services are critical to the completion and production phase of a well, as it provides the customer with initial well productivity data which ultimately impacts a reservoir’s capacity to produce hydrocarbons, such as oil, gas and condensate. Our traditional well testing and hydraulic equipment can service a multitude of operational scenarios, such as high and low temperature, high and low pressure, high hydrogen sulfide concentration and high volume. Currently, we own approximately 280 equipment spreads to support this broad range of services.

11

•Fluid Hauling. Our fluid hauling service line transports and stores water and various drilling, completion and production fluids utilizing our fleet of vacuum trucks, winch trucks, hydrovac trucks, and related assets, such as frac tanks. Currently, we own and lease approximately 200 tractors and own approximately 990 frac tanks.

•Fluid Disposal. We own 18 salt water disposal (“SWD”) wells with a daily maximum permitted disposal volume of approximately 300,000 bpd. Our SWD wells are located in the Eagle Ford (6), Permian (4), Haynesville (3), Marcellus (2), MidCon (2) and Rockies (1) regions.

Geographic Areas of Operation

We offer our Water Solutions services in most of the major unconventional shale plays in the continental U.S., as illustrated by a “✓” in the chart below.

|

|

Geographic Region |

|||||||

|

Services Provided |

Permian |

MidCon |

Bakken |

Eagle Ford |

Marcellus / |

Haynesville |

Rockies |

|

|

Water Sourcing |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

|

|

Water Transfer |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

|

|

Water Containment |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

|

|

Water Monitoring |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

|

|

Water Treatment and Recycling |

✓ |

✓ |

— |

✓ |

✓ |

✓ |

✓ |

|

|

Well Testing and Flowback |

✓ |

✓ |

* |

✓ |

✓ |

✓ |

✓ |

|

|

Fluid Hauling |

✓ |

✓ |

✓ |

✓ |

* |

✓ |

✓ |

|

|

Frac Tanks |

✓ |

✓ |

✓ |

✓ |

* |

✓ |

✓ |

|

|

Fluid Disposal |

✓ |

✓ |

— |

✓ |

✓ |

✓ |

✓ |

|

*In these regions, we have retained facilities but are not currently conducting operations.

Customers

Our Water Solutions customers primarily include major integrated and independent U.S. and international oil and gas producers.

Competition

Many large domestic and international oilfield services companies offer some water‑oriented and environmental services, though these are generally ancillary to their core businesses. As a result, the water solutions industry is highly fragmented and our main competitors are typically smaller or mid‑sized and often private service providers that focus on water solutions and logistical services across a narrow geographic range. We seek to differentiate ourselves from our competitors by delivering the highest‑quality services and equipment possible, coupled with superior execution and operating efficiency in a safe working environment.

Oilfield Chemicals

Our Oilfield Chemicals segment is operated primarily under our subsidiary, Rockwater LLC, and develops, manufactures and provides a full suite of chemicals utilized in hydraulic fracturing, stimulation, cementing and well completions, including polymers that create viscosity, crosslinkers, friction reducers, surfactants, buffers, breakers and other chemical technologies, to leading pressure pumping service companies in the United States. We also provide

12

production chemicals solutions, which are applied to underperforming wells in order to enhance well performance and reduce production costs through the use of production treating chemicals, corrosion and scale monitoring, chemical inventory management, well failure analysis and lab services.

Service Lines

Our Oilfield Chemicals segment is divided into the following services lines:

•Completion Chemicals. Our completion chemicals service line develops, manufactures and provides a full suite of chemicals utilized in hydraulic fracturing, stimulation, cementing and well completions, including polymers that create viscosity, crosslinkers, friction reducers, surfactants, buffers, breakers and other chemical technologies, to leading pressure pumping service companies in the United States. Our product lines support the three major types of well completions (cross‑linked gel frac, linear fracs and slickwater fracs). We can provide 24/7/365 time‑critical logistical support to our customers. Our warehousing and service include inventory management with computerized tracking and monthly reporting. The use of automated communications systems combined with direct‑to‑wellsite delivery ensures seamless product availability for our customers, while our chemical expertise enables us to deliver a customized suite of products to meet customers’ technical and economical product needs. Our expertise in frac chemistry positions us to support our customers in the ever changing ways of how wells are completed with our wide range of manufactured products. We have two primary manufacturing facilities in Texas, five regional distribution centers and 29 heavy chemical transport trucks and provide products to our customers in all major U.S. shale basins.

•Production Chemicals. In our production chemicals service line, we analyze underperforming wells and design engineered chemical solutions to enhance production and well performance and reduce production costs. These chemical solutions include: production treating chemicals for use in oil and gas production; ancillary oilfield services including corrosion and scale monitoring, chemical inventory management and well failure analysis; and lab services. In the Permian, our centrally located lab provides complete water and bacteria analysis through the well life cycle beginning with frac water through the production cycle. Our strategy is to provide basin‑specific production chemicals solutions to operating companies that lower costs and increase production. Our solutions help customers avoid scaling and corrosion, hydrogen sulfide issues and paraffin build‑up. This service line differentiates our overall utility to operators by allowing us to manage the entire well life cycle. Our production chemicals service line complements our Water Solutions segment due to the pull‑through sales ability in the overlapping customer base, and it also complements our completion chemicals service line because we can advise customers on the completion fluid systems best suited for a well when it transitions from completion to production. We have two primary manufacturing facilities in Texas and one in Oklahoma. We serve the Permian, Eagle Ford and Mid‑Continent basins and offer analytical services, lab and field support through 23 field locations.

•Specialty Chemicals. Our specialty chemicals service line manufactures and distributes chemicals that are formulated specifically for the coiled tubing industry. We offer a complete line of fracturing, acid and coiled tubing products. We manufacture the emulsion polymers, xanthan gels and corrosion inhibitors that support the coil tubing operations.

13

Geographic Areas of Operation

We provide Oilfield Chemicals services in most of the major unconventional shale plays in the continental U.S. In the chart below, a “✓” indicates that we offer the service line in the indicated geographic region.

|

|

Geographic Region |

|||||||

|

Services Provided |

Permian |

MidCon |

Bakken |

Eagle Ford |

Marcellus / |

Haynesville |

Rockies |

|

|

Completion Chemicals |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

|

|

Production Chemicals |

✓ |

✓ |

— |

✓ |

— |

✓ |

— |

|

|

Specialty Chemicals |

✓ |

✓ |

— |

✓ |

— |

— |

— |

|

Customers

Our Oilfield Chemicals customers primarily include oilfield services companies, including pressure pumpers, and major integrated and independent U.S. and international oil and gas producers.

Competition

Our Oilfield Chemical segment has a variety of different competitors, from companies that are pure distributors of commodities and specialty chemicals, to large manufacturers. What makes Rockwater unique is that we offer a distribution arm as well as the ability to manufacture in-basin. We believe that the principal competitive factors in the markets we serve are technical expertise, equipment capacity, work force competency, efficiency, safety record, reputation, experience and price. Additionally, projects are often awarded on a bid basis, which tends to create a highly competitive environment. We seek to differentiate ourselves from our competitors by delivering the highest‑quality services and equipment possible, coupled with superior execution and operating efficiency in a safe working environment.

Wellsite Services

Our Wellsite Services segment provides a number of services across the U.S. and Canada and is operated primarily under our subsidiaries Peak, Affirm and Rockwater LLC. Peak provides workforce accommodations and surface rental equipment supporting drilling, completion and production operations to the U.S. onshore oil and gas industry. Affirm provides oil and gas operators with a variety of services, including crane and logistics services, wellsite and pipeline construction and field services. Operating under Rockwater LLC, we also offer sand hauling and logistics services in the Rockies and Bakken regions as well as water transfer, containment, fluids hauling and other rental services in Western Canada.

Service Lines

Our Wellsite Services segment is divided into the following service lines:

•Accommodations and Rentals. Our accommodations and rentals service line, operating under our subsidiary, Peak, provides workforce accommodations and surface rental equipment supporting drilling, completion and production operations to support onshore oil and gas activity. The services provided include fully furnished office and living quarters, fresh water supply and wastewater removal, portable power generation and light plants, internet, phone, intercom, surveillance and monitoring services and other long‑term rentals supporting field personnel.

•Wellsite Completion and Construction Services. Our wellsite completion and construction services service line, operating under our subsidiary, Affirm, supports our Water Solutions segment and provides oil and gas operators and midstream companies with a variety of services, including crane and logistics services,

14

wellsite and pipeline construction and field services. These services are performed to establish, maintain and improve production throughout the productive life of an oil or gas well, or to otherwise facilitate other services performed on a well.

•Sand Hauling. Our sand hauling service line, operating under our subsidiary, Rockwater LLC, provides proppant storage, transport, transloading, and sand and proppant supply and transportation logistics through our fleet of trucks.

•Canada Fluids Logistics. Our Canadian operations, operating under Rockwater Energy Solutions Canada, Inc., a subsidiary of Rockwater LLC, provide comprehensive fluids logistics through our fleet of tank trucks, vacuum trucks, hydro‑vac trucks, hot oilers, winch trucks and pressure trucks. Additionally, we provide water transfer, containment and other rental services throughout Western Canada.

Geographic Areas of Operation

We provide Wellsite Services in most of the major unconventional shale plays in the continental U.S. and in Western Canada. In the chart below, a “✓” indicates that we offer the service line in the indicated geographic region.

|

|

Geographic Region |

||||||||

|

Services Provided |

Permian |

MidCon |

Bakken |

Eagle Ford |

Marcellus / |

Haynesville |

Rockies |

Western |

|

|

Accommodations & Rentals |

✓ |

✓ |

— |

✓ |

✓ |

✓ |

✓ |

— |

|

|

Wellsite Completion & Construction Services |

✓ |

✓ |

— |

✓ |

✓ |

✓ |

✓ |

— |

|

|

Sand Hauling |

— |

— |

✓ |

— |

— |

— |

✓ |

— |

|

|

Canada Fluids Logistics |

— |

— |

— |

— |

— |

— |

— |

✓ |

|

Customers

Our Wellsite Services customers include major integrated and independent U.S. and international oil and gas producers, as well as midstream and other oilfield services companies.

Competition

Historically, our competition has varied significantly by service line. The market for accommodations and rentals has been serviced by a relatively fragmented competitor base ranging from small local companies and privately‑owned regional service companies to large private and public companies operating across diverse geographies. Our main competitors in the market for wellsite completion and construction services are typically smaller or mid‑sized, and often private, service providers that focus on construction and field services across a narrow geographic range. Our competitors in the market for sand hauling are typically regionally focused smaller or mid‑sized service providers. Our primary competitors in our Canadian operations are regionally focused smaller or mid‑sized service providers. We seek to differentiate ourselves from our competitors by delivering the highest‑quality services and equipment possible, coupled with superior execution and operating efficiency in a safe working environment.

Significant Customer

There were no customers that accounted for 10.0% or more of our consolidated revenues for the years ended December 31, 2017 and 2016. For the year ended December 31, 2015, one of our customers accounted for approximately 10.6% of our total consolidated revenues.

15

Sales and Marketing

Our sales activities are directed through a network of sales representatives and business development personnel, which provides us coverage at both the corporate and field level of our customers. Sales representatives work closely with local operations managers to target potential opportunities through strategic focus and planning. Customers are identified as targets based on their drilling and completion activity, geographic location, and economic viability. Direction of the sales team is conducted through multiple weekly meetings and daily reporting. Our sales strategy is also supported by a proprietary database that we have developed based upon current rig and permit activity and the location of our strategic water sources.

Our marketing activities are performed by an internal marketing group with input from a steering committee. Our strategy is based on building a national brand though multiple media outlets including our website, blog and social media accounts, radio, print and billboard advertisements, and various industry‑specific conferences, publications and lectures.

Engineered Water Solutions

Our Engineered Water Solutions group is comprised of professionals with significant technical and project development experience. The team consists of professionals with advanced degrees and experience in areas as diverse as geology, geography, petroleum and chemical engineering, computer science, environmental science, geographic information systems and regulatory affairs. This group has been designed to help customers develop and execute water solutions for wide‑scale development projects, with our professionals integrating themselves into our customers’ operations teams at the outset of the planning process.

Environmental and Occupational Safety and Health Matters

Our water‑related and wellsite completion and construction operations in support of oil and gas exploration, development and production activities pursued by our customers are subject to stringent and comprehensive federal, state, provincial and local laws and regulations in the United States and Western Canada governing occupational safety and health, the discharge of materials into the environment and environmental protection. Numerous governmental entities, including the U.S. Environmental Protection Agency (the “EPA”) and analogous state agencies, have the power to enforce compliance with these laws and regulations and the permits issued under them, often requiring difficult and costly actions. These laws and regulations may, among other things (i) require the acquisition of permits to take fresh water from surface water and groundwater, construct pipelines or containment facilities, drill wells and other regulated activities; (ii) restrict the types, quantities and concentration of various substances that can be released into the environment or injected into non‑producing formations; (iii) limit or prohibit our operations on certain lands lying within wilderness, wetlands and other protected areas; (iv) require remedial measures to mitigate pollution from former and ongoing operations; (v) impose specific safety and health criteria addressing worker protection; and (vi) impose substantial liabilities for pollution resulting from our operations. Any failure to comply with these laws and regulations may result in the assessment of sanctions, including administrative, civil and criminal penalties, the imposition of investigatory, remedial or corrective action obligations or the incurrence of capital expenditures; the occurrence of delays in the permitting or performance of projects; and the issuance of orders enjoining performance of some or all of our operations in a particular area.

The trend in United States and Canadian environmental regulation in recent years has been typically to place more restrictions and limitations on activities that may affect the environment, and thus any changes in environmental laws and regulations or re‑interpretation of enforcement policies that result in more stringent and costly construction, completion or water management activities, or waste handling, storage transport, disposal, or remediation requirements could have a material adverse effect on our financial position and results of operations. We may be unable to pass on such increased compliance costs to our customers. Moreover, accidental releases or spills may occur in the course of our operations, and we cannot assure you that we will not incur significant costs and liabilities as a result of such releases or spills, including any third‑party claims for damage to property, natural resources or persons. Our customers may also incur increased costs or delays or restrictions in permitting or operating activities as a result of more stringent

16

environmental laws and regulations, which may result in a curtailment of exploration, development or production activities that would reduce the demand for our services.

United States Operations

The following is a summary of the more significant existing environmental and occupational safety and health laws, as amended from time to time, to which our operations in the United States are subject and for which compliance may have a material adverse impact on our capital expenditures, results of operations or financial position.

Hazardous substances and wastes. The Resource Conservation and Recovery Act (“RCRA”), and comparable state statutes, regulate the generation, transportation, treatment, storage, disposal and cleanup of hazardous and non‑hazardous wastes. Pursuant to rules issued by the EPA, the individual states administer some or all of the provisions of RCRA, sometimes in conjunction with their own, more stringent requirements. Drilling fluids, produced waters, and most of the other wastes associated with the exploration, development, and production of oil or gas, if properly handled, are currently exempt from regulation as hazardous waste under RCRA, and instead are regulated under RCRA’s less stringent non‑hazardous waste provisions, state laws or other federal laws. However, it is possible that certain oil and gas drilling and production wastes now classified as non‑hazardous could be classified as hazardous wastes in the future. For example, following the filing of a lawsuit in the U.S. District Court for the District of Columbia in May 2016 by several non‑governmental environmental groups against the EPA for the agency’s failure to timely assess its RCRA Subtitle D criteria regulations for oil and gas wastes, the EPA and the environmental groups entered into an agreement that was finalized in a consent decree issued by the District Court in December 2016. Under the decree, the EPA is required to propose no later than March 15, 2019, a rulemaking for revision of certain Subtitle D criteria regulations pertaining to oil and gas wastes or sign a determination that revision of the regulations is not necessary. If the EPA proposes a rulemaking for revised oil and gas waste regulations, the Consent Decree requires that the EPA take final action following notice and comment rulemaking no later than July 15, 2021. A loss of the RCRA exclusion for drilling fluids, produced waters and related wastes could result in an increase in our and our oil and gas producing customers’ costs to manage and dispose of generated wastes, which could have a material adverse effect on our and our customers’ results of operations and financial position. In the course of our operations, we generate some amounts of ordinary industrial wastes, such as paint wastes, waste solvents and waste oils that may be regulated as hazardous wastes.

Wastes containing naturally occurring radioactive materials (“NORM”) may also be generated in connection with our operations. Certain processes used to produce oil and gas may enhance the radioactivity of NORM, which may be present in oilfield wastes. NORM is subject primarily to individual state radiation control regulations. In addition, NORM handling and management activities are governed by regulations promulgated by the Occupational Safety and Health Administration (“OSHA”). These state and OSHA regulations impose certain requirements concerning worker protection, the treatment, storage and disposal of NORM waste, the management of waste piles, containers and tanks containing NORM, as well as restrictions on the uses of land with NORM contamination.

The Comprehensive Environmental Response, Compensation and Liability Act (“CERCLA”), also known as the Superfund law, and comparable state laws impose liability, without regard to fault or legality of conduct, on classes of persons considered to be responsible for the release of a “hazardous substance” into the environment. These persons include the current and past owner or operator of the site where the hazardous substance release occurred and anyone who disposed or arranged for the disposal of a hazardous substance released at the site. Under CERCLA, such persons may be subject to joint and several, strict liability for the costs of cleaning up the hazardous substances that have been released into the environment, for damages to natural resources and for the costs of certain health studies. CERCLA also authorizes the EPA and, in some instances, third parties to act in response to threats to the public health or the environment and to seek to recover from the responsible classes of persons the costs they incur. In addition, neighboring landowners and other third parties may file claims for personal injury and property damage allegedly caused by the hazardous substances released into the environment. We generate materials in the course of our operations that may be regulated as hazardous substances.

We currently own, lease, or operate numerous properties that have been used for activities supporting oil and gas exploration, development and production for a number of years. Although we believe that we have utilized operating and waste disposal practices that were standard in the industry at the time, hazardous substances, wastes, or petroleum

17

hydrocarbons may have been released on, under or from the properties owned or leased by us, or on, under or from other locations, including off‑site locations, where we conduct services for our customers or where such substances have been taken for treatment or disposal. In addition, some of our properties have been operated by third parties or by previous owners or operators whose treatment and disposal of hazardous substances, wastes, or petroleum hydrocarbons was not under our control. These properties and the substances disposed or released on, under or from them may be subject to CERCLA, RCRA and analogous state laws. Under such laws, we could be required to undertake response actions or corrective measures, which could include removal of previously disposed substances and wastes, cleanup of contaminated property or performance of remedial operations to prevent future contamination, the costs of which could be material.

Water discharges and use. The Federal Water Pollution Control Act, also known as the Clean Water Act (“CWA”), and analogous state laws, impose restrictions and strict controls with respect to the discharge of pollutants, including spills and leaks of oil and hazardous substances, into state waters and waters of the United States. The discharge of pollutants into regulated waters is prohibited, except in accordance with the terms of a permit issued by the EPA or an analogous state agency. Spill prevention, control and countermeasure plan requirements imposed under the CWA require appropriate containment berms and similar structures to help prevent the contamination of navigable waters in the event of a petroleum hydrocarbon tank spill, rupture or leak. In addition, the CWA and analogous state laws require individual permits or coverage under general permits for discharges of storm water runoff from certain types of facilities.

The CWA also prohibits the discharge of dredge and fill material in regulated waters, including wetlands, unless authorized by permit. In June 2015, the EPA and the U.S. Army Corps of Engineers (the “Corps”) published a final rule attempting to clarify the federal jurisdictional reach over waters of the United States, but legal challenges to this rule followed, and the rule was stayed nationwide by the U.S. Sixth Circuit Court of Appeals in October 2015 pending resolution of the court challenges. In January 2017, the U.S. Supreme Court accepted review of the rule to determine whether jurisdiction rests with the federal district or appellate courts, and, in a decision issued on January 22, 2018, held that legal challenges of the rule must be heard at the district rather than appellate court level. Additionally, following the issuance of a presidential executive order to review the rule, the EPA and the Corps proposed a rulemaking in June 2017 to repeal the June 2015 rule. The EPA and the Corps also announced their intent to issue a new rule defining the CWA’s jurisdiction. On February 6, 2018, the EPA and Corps published a final rule specifying that the contested June 2015 rule would not take effect until February 6, 2020. As a result, future implementation of the June 2015 rule is uncertain at this time. To the extent this rule or a revised rule expands the scope of the CWA’s jurisdiction, we could face increased costs and delays with respect to obtaining permits for dredge and fill activities in wetland areas in connection with any expansion activities. Federal and state regulatory agencies can impose administrative, civil and criminal penalties for non‑compliance with discharge permits or other requirements of the CWA and analogous state laws and regulations.

The Oil Pollution Act of 1990 (“OPA”) amends the CWA and sets minimum standards for prevention, containment and cleanup of oil spills in waters of the United States. The OPA applies to vessels, offshore facilities, and onshore facilities, including E&P facilities that may affect waters of the United States. Under OPA, responsible parties including owners and operators of onshore facilities may be held strictly liable for oil cleanup costs and natural resource damages as well as a variety of public and private damages that may result from oil spills. The OPA also requires owners or operators of certain onshore facilities to prepare Facility Response Plans for responding to a worst‑case discharge of oil into waters of the United States.

Salt water disposal wells and induced seismicity. Salt water disposal via underground injection is regulated pursuant to the Underground Injection Control (“UIC”) program established under the U.S. Safe Drinking Water Act (the “SDWA”) and analogous state and local laws and regulations. The UIC program includes requirements for permitting, testing, monitoring, record keeping and reporting of injection well activities, as well as a prohibition against the migration of fluid containing any contaminant into underground sources of drinking water. State regulations require a permit from the applicable regulatory agencies to operate underground injection wells. Although we monitor the injection process of our wells, any leakage from the subsurface portions of the injection wells could cause degradation of fresh groundwater resources, potentially resulting in suspension of our UIC permit, issuance of fines and penalties from governmental agencies, incurrence of expenditures for remediation of the affected resource and imposition of liability by

18

third‑parties claiming damages for alternative water supplies, property and personal injuries. A change in UIC disposal well regulations or the inability to obtain permits for new disposal wells in the future may affect our ability to dispose of produced waters and other substances, which could affect our business.

Furthermore, in response to recent seismic events near underground disposal wells used for the disposal by injection of produced water resulting from oil and gas activities, federal and some state agencies are investigating whether such wells have caused increased seismic activity, and some states have restricted, suspended or shut down the use of such disposal wells. In response to these concerns, regulators in some states have imposed, or are considering imposing, additional requirements in the permitting of produced water disposal wells or otherwise to assess any relationship between seismicity and the use of such wells. For example, Oklahoma issued new rules for wastewater disposal wells in 2014 that imposed certain permitting and operating restrictions and reporting requirements on disposal wells in proximity to faults and also, from time to time, has developed and implemented plans directing certain wells where seismic incidents have occurred to restrict or suspend disposal well operations. The Texas Railroad Commission adopted similar rules in 2014. In December 2016, the Oklahoma Corporation Commission’s Oil and Gas Conservation Division and the Oklahoma Geological Survey released well completion seismicity guidance, which requires operators to take certain prescriptive actions, including an operator’s planned mitigation practices, following certain unusual seismic activity within 1.25 miles of hydraulic fracturing operations. In addition, the Oklahoma Corporation Commission’s Oil and Gas Conservation Division issued an order in February 2017 limiting future increases in the volume of oil and natural gas wastewater injected below ground into the Arbuckle formation in an effort to reduce the number of earthquakes in the state, and imposed further reductions in the Edmonds area of the state in August 2017. In addition, ongoing lawsuits allege that disposal well operations have caused damage to neighboring properties or otherwise violated state and federal rules regulating waste disposal. The adoption and implementation of any new laws, regulations or directives that restrict our ability to dispose of wastewater gathered from our customers by limiting volumes, disposal rates, disposal well locations or otherwise, or requiring us to shut down disposal wells, could have a material adverse effect on our business, financial condition, and results of operations.

Hydraulic fracturing activities. As noted, hydraulic fracturing involves the injection of water, sand or other proppants and chemical additives under pressure into targeted geological formations to fracture the surrounding rock and stimulate production. Hydraulic fracturing is currently generally exempt from regulation under the UIC program established under the SDWA. Hydraulic fracturing is regulated by state oil and gas commissions or similar agencies.

However, several federal agencies have asserted regulatory authority over certain aspects of the process. For example, in 2014, the EPA asserted regulatory authority pursuant to the SDWA’s UIC program over hydraulic fracturing activities involving the use of diesel and issued guidance covering such activities. Additionally, in June 2016, the EPA published an effluent limit guideline final rule prohibiting the discharge of wastewater from onshore unconventional oil and gas extraction facilities to publicly owned wastewater treatment plants and, in 2014, published an Advance Notice of Proposed Rulemaking regarding the Toxic Substances Control Act (“TSCA”) reporting of the chemical substances and mixtures used in hydraulic fracturing. Also, the Bureau of Land Management (“BLM”) published a final rule in 2015 that established new or more stringent standards relating to hydraulic fracturing on federal and American Indian lands. However, in June 2016, a Wyoming federal judge struck down this final rule, finding that the BLM lacked authority to promulgate the rule, the BLM appealed this decision to the U.S. Court of Appeals for the Tenth Circuit in July 2016, the appellate court issued a ruling in September 2017 to vacate the Wyoming trial court decision and dismiss the lawsuit challenging the 2015 rule in response to the BLM’s issuance of a proposed rulemaking to rescind the 2015 rule and, in December 2017, the BLM published a final rule rescinding the 2015 rule. In January 2018, litigation challenging the BLM’s recission of the 2015 rule was brought in federal court. In January 2018, litigation challenging the BLM’s recissionof the 2015 rule was brought in federal court.

From time to time, legislation has been introduced, but not enacted, in Congress to provide for federal regulation of hydraulic fracturing and to require disclosure of the chemicals used in the fracturing process. In the event that new federal restrictions on the hydraulic‑fracturing process are adopted in areas where we or our customers conduct business, we or our customers may incur additional costs or permitting requirements to comply with such federal requirements that may be significant in nature and our customers could experience added delays or curtailment in their exploration, development, or production activities, which would in turn reduce the demand for our services.

19